Love everything about this store: Quality, Service, Shipping… Just want more “ Mix and Match” items.

With a recent rise in conscious consumerism, one of the best places to begin when switching to a more sustainable lifestyle without sacrificing on comfort and softness is with the sheets you sleep on. If you’ve ever done a Google search for sustainable bedding, odds are you’ll come across TENCEL™ Lyocell. We’re not surprised, TENCEL™ Lyocell fibers is a very popular choice for eco-conscious shoppers. It is versatile and gentle on skin and used in a wide range of products from apparel to bedding. If you’ve never heard of TENCEL™ Lyocell, don’t worry: you’re not the only one wondering what this is. In this blog post, we’ll go over what TENCEL™ branded Lyocell is and how it’s made.

What are TENCEL™ Lyocell Fibers?

TENCEL™ is a specialty fiber brand which consists of lyocell and modal fibers. TENCEL™ Lyocell fibers are produced via sustainable closed-loop manufacturing process, which transformed wood pulp to cellulosic fibers. It was first developed by Austria based company, Lenzing AG between 1990-2000. With concerns over the status of the environment at the time, TENCEL™ Lyocell served as a sustainable and environmentally responsible alternative to other textile materials. In recent years, the popularity for fabric made with TENCEL™ Lyocell fibers has skyrocketed largely due to the shift to more sustainable and eco-conscious lifestyles. From their botanic origin, to the low environmental impact of production, to eventual biodegradability on disposal, TENCEL™ fibers exemplify sustainability in the textile industry.

*For more information, refer to www.tencel.com

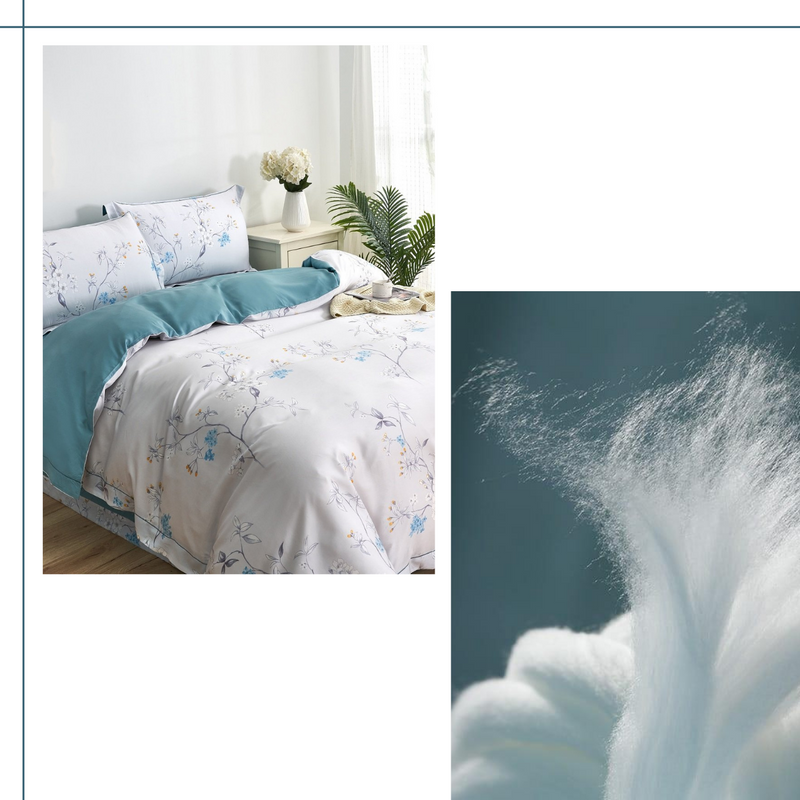

TENCEL™ Lyocell fibers have gained a commendable reputation for its award-winning closed loop production process, which transforms wood pulp into cellulosic fibers with high resource efficiency and low environmental impact. The initial fiber is made by harvesting renewable wood pulp sourced from sustainable forests. This wood pulp is dissolved and mixed with a solvent to create a wet mixture. It then undergoes a unique drying process called “spinning” in order to be spun into yarn. This solvent-spinning process recycles process water and reuses the solvent at a recovery rate of more than 99%. In the final stages, the fiber is spun into yarn and is then transformed into fabric, which is used for all different types of products from apparel to bedding. At Qbedding, we have a diverse collection of TENCEL™ Lyocell bedding to suit any bedroom style.

Overall, fabric made with TENCEL™ Lyocell, can be used to create clothing, bedding, accessories, and more. According to Lenzing, “TENCEL™ Lyocell fibers are known for their natural comfort, are versatile and can be combined with a wide range of textile fibers such as cotton, polyester, acrylic, wool, and silk to enhance the aesthetics and functionality of fabrics. Unique physical properties of TENCEL™ Lyocell fibers lead to their great strength and gentleness to skin.” We’ll soon be covering the leading benefits of TENCEL™ Lyocell, so make sure to subscribe to our newsletter to stay up to date on our newest blog posts.